Drainable HouseWrap is about recent technology developments in WRB (Water Resistive Barriers) and exterior water draining behind cladding.

HydroGap by Benjamin Obdyke (B.O.) is a major step forward in drainable housewraps with integral WRB (Water Resistive Barrier) and water vapor breathability/ protection.

HOME ARCHITECTS ® is in the process of shifting from more expensive multiple step/ multiple component High Performance Rain Screen system/ materials to the more value engineered B.O. HydroGap. It appears the B.O. has created a better “mousetrap” for a more effective price point.

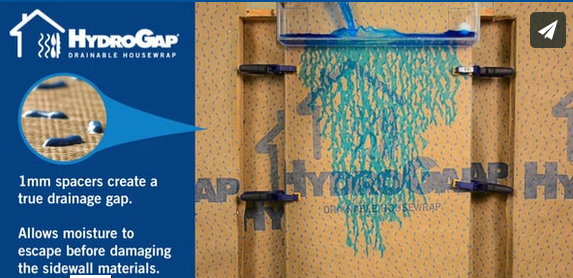

In one layer, they have integral bulk water protection and drainage plane. They have integral 1mm plastic spacers spread over their housewrap, that keeps the exterior wall cladding spaced by that 1mm from the housewrap, thereby facilitating drainage of water that penetrates the cladding and out the bottom of the wall system. All in a one-layer application.

1mm = about 1/25th of an inch. This means that no field installed insect screening is necessary (as is required with the more costly HP Rain Screen systems) because the default insect grid screening protection used in architectural projects is 1/16th inch. 1mm is smaller than this, which means it should be almost impervious to normal insect infestation. Certainly better than the typical insect protection grid used by most Architects designing houses and other projects. And once again, more costly field application of insect screening is avoided, as is required with the 1/4″ thick HP Rain Screen systems.

Perm rating of HydroGap: 16. Now then, the IRC calls for a WRB (Water Resistive Barrier) of 15# asphaltic felt. And this has a Perm Rating of around 5. That’s for vapor permeance. And you really shouldn’t be using anything LESS permeable to vapor (a lower number) so that water inside the wall system can breath and dry out (either toward the interior or exterior). So, the B.O. HydroGap, while resistive to bulk water, also helps the wall system to breath and dry out better. Once again: a better mousetrap. Architects can make this informed change. For instance: while our firm is not a fan of Tyvek, which is the main housewrap used by Builders these days, it has a Perm Rating (per Dow) of 58. The fact that building departments across the USA and world allow this perm rating of more than 11 times that of what the IRC indicates, leads us to believe that we would be just fine, in terms of code issues, specifying a quality membrane like HydroGap with its Perm Rating of 16. Do Not confuse water penetration with vapor penetration; they are Not the same.

By the way, HydroGap’s Water Resistance: PASS, per ASTM D-779 (Boat Test), PASS, per AC38 Section 3.3.2 (4.2.1) (Hydrostatic Head), PASS, per CCMC Guide MF07102 (Water Ponding). No Penetration. In other words, in no less than 3 different WRB (Water Resistive Barrier) tests, HydroGap successfully holds back water from entering the system. See B.O. website page: http://www.hydrogap.com/

Now then, let’s also throw into the mix the fact that many Architects and higher quality Builders are now using Continuous Insulation. In our firm’s practice, we specify 1″ of Formular XPS t & g closed cell Styrofoam (and don’t tape it). This Styrofoam product has a Perm Rating of 1.1, which means it doesn’t breath very much, which is another reason to not tape it’s t&g joints, in hopes that it will breath a little better. Also, if you tape the joints, you are introducing reverse shingling, which means that as the adhesive of the tape breaks down over time (and shrinkage of foam boards), that water hitting the face of the foam can run down behind the tape, onto the foam board, then into the wood (or other material) and into the wall system, wreaking havoc.

You want to put the B.O. HydroGap immediately under your exterior cladding, in order to help drain rain water penetrating the cladding and keep it outboard of your wall system, that means the HydroGap will be located outboard of your C.I. (Continuous Insulation). The HydroGap as a 16 Perm Rating and the 1″ XPS thermal sheathing has Perm Rating of 1.1. So, the combined result will be not a very breathable wall, mainly due to the thermal sheathing, which is required by IECC (International Energy Conservation Code) as one of the main options to better thermal performance. That’s an issue that has not really been adequately addressed. But for the time being, we believe that’s the method we’re going to be using henceforth, based on current technology.

We’re betting that by ELIMINATING the likelihood of water penetrating our future walls from the exterior, we’re not going to be terribly concerned about getting potentially non-existent water out of the outer layers of our walls, which will have that drainage plane. And for any moisture already in the wall system when built or coming from the interior, the wall system should be able to breathe and dry towards the interior, as long as the recommended integral kraft paper (asphaltic coated paper on the rear of fiberglass insulation) is used as recommended toward the interior, which does permit some breathability. This was mentioned for the very likely fact that more and more framed (and other types) walls will be using C.I. in the form of closed cell foam insulation rigid sheets over the structural sheathing.

So, HydroGap appears like a very good direction in which to go.